Let's undestand your products!

We perform all your product characterization tests for you.

Let's go for your innovation!

We support your innovation from idea to prototype with outstanding scientific expertise and professional project management.

Let's discuss your ideas!

We are experts from a high-tech university, with scientific expertise, long experience and a wide network of contacts.

Our facilities

ECC laboratories are fully-equipped with cutting-edge tools and technologies, enabling accurate processing, testing, analysis, and characterization of rubber materials.

ECC OFFERS A WIDE RANGE OF SERVICES TO SUPPORT YOUR NEEDS

Material processing

ECC has fully equipped mixing lines to develop a wide range of rubber compounds. The mixing is carried out in accordance with standards, using in-house processing method or adhering to any customer-specific requirements.

Compounding equipment

- Internal mixers

Internal mixer is a crucial piece of equipment used to mix and process raw materials to produce rubber compounds.

It provides efficient and uniform mixing.

Benefits:

- Efficient and uniforming mixing resulting in a homogenized rubber compound with consistent properties.

- Time-saving process.

- Reduced Labor Intensity since it automate the mixing process.

Our mixers are laboratory scale and the torque and temperature are recorded.

EQUIPMENT

DESCRIPTION

Brabender 350S

- Effective mixing volume: 390 cm3

- Rotor type: Banbury

- Rotos speed: 0 – 150 rpm

- Temperature control: 25 – 120 °C

- Maximum torque: 400 Nm

Brabender 350S

- Effective mixing volume: 390 cm3

- Rotor type: Banbury

- Rotos speed: 0 – 150 rpm

- Temperature control: 25 – 120 °C

- Maximum torque: 400 Nm

Brabender Plastograph EC plus

- Effective mixing volume: 55/80 cm3

- Rotor type: Banbury / High shear

- Rotos speed: 0 – 150 rpm

- Temperature control: 25 – 300 °C

- Maximum torque: 200 Nm

- Mixing mills

Mixing mill, also known as two-roll mill, is an integral equipment of the rubber industry for the mixing and processing of materials.

It offers an effective solution for mixing, refining and homogenizing rubber compounds.

Benefits:

- Versatile equipment that can handle a wide range of rubber compounds.

- Uniform mixing and distribution of additives and fillers, leading to consistent compound properties.

Our mixing mills are laboratory scale.

Equipment

Description

Schwabenthan

- Diameter rolls: 80 mm

- Width of rolls: 200 mm

- Rotational speed: 20 rpm

- Friction coefficient: 1.13

- Nip adjustment: 0 – 10 mm

- Temperature 25 – 150 °C

Polymix 80T

- Diameter rolls: 80 mm

- Width of rolls: 300 mm

- Rotational speed: 20 rpm

- Friction coefficient: 1.11

- Nip adjustment: 0 – 10 mm

- Temperature 25 – 150 °C

- Compression molding

Compression molding is a widely used manufacturing process for shaping various rubber compound materials. Rubber compounds can be vulcanized or shaped at a certain temperature and pressure.

Compression molding is a widely used manufacturing process for shaping various rubber compound materials. Rubber compounds can be vulcanized or shaped at a certain temperature and pressure.It is particularly suitable for relatively simple and large-sized parts with excellent dimensional accuracy and surface finish.

Equipment

Description

Wickert WLP1600

- Temperature range: 25 – 220 °C

- Pressure: 50 – 300 Bar

- Heated plates dimensions: 500 x 500 mm

- Daylight opening: 300 mm

Material characterization

ECC has fully equipped testing service to provide a comprehensive characterization of rubber compounds. The testing is carried out in accordance with standards, using in-house testing method or adhering to any customer-specific requirements.

Processability test

- Mooney viscometer

Mooney viscometer is a common equipment for evaluating the processability and the correlation between viscosity values and molecular mass of rubber compounds.

Mooney viscometer is a common equipment for evaluating the processability and the correlation between viscosity values and molecular mass of rubber compounds.Mooney viscosity measures the viscosity of rubber compounds, offering valuable insights into their flow characteristics and overall processability.

It helps rubber manufacturers ensure consistent product performance (quality control) and allows them to adjust the formulation if necessary to achieve desired processing properties.

Mooney scorch can be used to measure the incipient cure time and the rate of cure during very early stages of vulcanization.

Stress relaxation can be correlated with the visco-elastic characteristics of the rubber compound. It is related to the rubber structure characteristics such as molecular mass distribution, chain branching, and gel content.

Equipment

Description

Mooney viscometer PREMIER™ MV (Alpha Technologies)

Measurements:

- Mooney Viscosity

- Mooney Scorch

- Stress Relaxation

Specifications:

- Temperature range: 25 – 200 °C

- Rotational speed: 0.01 – 20 rpm

- Sample size: 25 cc

- Rotor types: Large / Small

- Rubber Process Analyzer (RPA)

Rubber Process Analyzer (RPA) is an important and highly versatile tool in the development of rubber compounds which offer detailed insights into the curing process and quality control in rubber industry.

Rubber Process Analyzer (RPA) is an important and highly versatile tool in the development of rubber compounds which offer detailed insights into the curing process and quality control in rubber industry. This information help rubber manufacturers optimize their formulation and processing parameters to achieve the desired mechanical properties in the final product.

RPA is used for quantifying vulcanization characteristics, Payne effect measurements to ensure thorough filler dispersions, and predicting processability.

Vulcanization characteristics

The vulcanization characteristics provide valuable information about the vulcanization process of elastomeric compounds and a method to ensure consistency and quality control in rubber manufacturing processes.

These are compound-specific properties that determine, among other things, the vulcanization level and how long a specific product or test piece must be vulcanized.

Parameters:

- Minimum torque (ML): Indicator of the viscosity of the uncured composite.

- Maximum torque (MH): The peak torque value, representing the maximum state of cure. It correlates with the rubber's mechanical strength and other physical properties.

- Scorch time (ts2): The time necessary to reach a 2 unit increase in torque above minimum (this is the time a compound has to take the shape of a mold).

- Optimal vulcanization time (t90): The time taken to achieve 90% of its maximum torque or cure. It is an essential parameter as it determines the time required for the vulcanization process and influences the production rate.

Payne effect

The Payne effect is a phenomenon observed in filled rubber compounds. Fillers, such as carbon black, silica, or other reinforcing agents, are commonly added to rubber formulations to improve mechanical properties. However, the interaction between the fillers can significantly influence the mechanical behavior of the rubber compounds.

Payne effect It is the difference in modulus of a crosslinked rubber system when it is subjected to increasing deformation amplitude. The difference indicating a breakdown of agglomerates into primary particles and it is caused by the so-called filler-filler interaction within the polymer network.

EQUIPMENT

DESCRIPTION

Rubber Process Analyzer RPA 2000 (Alpha Technologies)

Measurements:

- Cure (isothermal, ramp, step)

- Strain (sweep, offset, LAOS)

- Frequency Sweep

- Stress Relaxation

Specifications:

- Frequency: 0.016 – 50 Hz

- Amplitude: 0.04 – 90 °

- Temperature: Ambient – 230 °C

- Torque: 0.05 – 200 dNm

- Sample volume: 4.5 cc

- Pressure: 4.5 Bar

- Sample pressure: Yes

Rubber Process Analyzer RPA-Elite (TA Instruments)

Measurements

- Cure (isothermal, ramp, step)

- Strain (sweep, offset, LAOS)

- Frequency Sweep

- Stress Relaxation

Specifications:

- Frequency: 0.001 – 50 Hz

- Amplitude: ±0.005 – ±360 °

- Strain: ±0.07 – ±5000 %

- Temperature: Ambient – 230 °C

- Torque: 0.0001 – 25 Nm

- Sample volume: 4.5 cm3

- Pressure: 2 – 8 Bar

- Sample pressure: Yes

SaMple preparation

- Preparation of test specimens

Test specimens preparation according to international standards or customer-specific requirements is a key element for laboratory testing.

Test specimens preparation according to international standards or customer-specific requirements is a key element for laboratory testing.Equipment

Description

Multi-Head Die Cutter (Gibitre Instruments)

Specimen Cutting Dies - Cutters:

Tensile

- Dummbell Type II ISO 37

- Dummbell Type III ISO 37

- Dummbell ASTM D1708

Tear

- Tear DIN 53515

- Tear Delft ISO 816

- Trouser ASTM D1938

Strip

- Strip ASTM D 0882

Physical characterization

- Universal testing machine

Tensile stress-strain test is used to determine the modulus, tensile strength, elongation at break of vulcanized compounds.

However, tensile properties alone may not directly relate to the total end-use performance of the product because of the wide range of potential performance requirements in actual use.

Tear strength test is used to determine the tear strength of vulcanized compounds.

Since tear strength may be affected to a large degree by stress-induced anisotropy of the rubber as well as by stress distribution, strain rate, size of the specimen, and direction of testing, the results obtained in a tear test can only be regarded as a measure of the strength under particular conditions. Usually tear properties are reported as file force required to pull a rubber test piece apart using a tensile testing instrument under controlled conditions.

Adhesion test allows determine the force necessary to separate a rubber from other surfaces (fabric, fibre, wire, or sheet metal). The test provides valuable data for development and quality control of rubber compounds. It also serves as a screening test for the evaluation of various bonding agents, techniques, or both.

Compression test allows study the compression-deflection of rubber compounds. It determine the force required to cause a specified deflection in rubber compounds and is useful in comparing stiffness of rubber materials in compression. This test can be used by rubber technologists to aid in development of materials for compressive applications.

These properties depend both on the material and the conditions of test and therefore should be compared only when tested under the same conditions.

Equipment

Description

Universal Testing Machine Zwick Z01 (Zwick/Roell)

Specifications:

- Force cell: 0.5 kN

- Grip type: Customizable

- Extensometer type: Clip

- Maximum travel: 1450 mm

- Maximum Speed: 1800 mm

- Temperature: Ambient

Universal Testing Machine Zwick Z10 (Zwick/Roell)

Specifications:

- Force cell: 0.1, 1, 10 kN

- Grip type: Customizable

- Extensometer type: Clip

- Maximum travel: 1450 mm

- Maximum Speed: 2000 mm

- Temperature: - 30 – 150 °C

- Hardness

Hardness test is based on the penetration of a specific type of indentor when forced into the material under specified conditions. This is an empirical test for the control process.

Hardness test is based on the penetration of a specific type of indentor when forced into the material under specified conditions. This is an empirical test for the control process.rdness generally denotes the resistance of material to local deformation, being measured as the resistance to penetration either by a loaded indentor (indentation hardness) or by a loaded sharp point moving over the surface (scratch hardness). Both these forms of tests are discussed below. Since hardness in this sense is related to the elastic modulus, it increases with increasing crosslink density, so that fully crosslinked polymers (ebonite) are the hardest, and it is reduced by plasticizers. Measurement of hardness by rebound resilience is done with metals and does not apply to high polymers, because their hardness and resilience are not directly related.

Equipment

Description

Digital Hardness Tester to Shore (Zwick/Roell)

Specifications:

- Measurement time adjustable

- Shore A: ISO R 868 / DIN 53505

- Shore D: ISO R 868 / DIN 53505

- Abrasion resistance

Abrasion test is used to estimate the relative abrasion resistance of different vulcanized rubber compounds. Since conditions of abrasive wear in service are complex and vary widely, no direct correlation between these tests and actual performance can be assumed.

Abrasion test is used to estimate the relative abrasion resistance of different vulcanized rubber compounds. Since conditions of abrasive wear in service are complex and vary widely, no direct correlation between these tests and actual performance can be assumed. This test is suitable for comparative testing, quality control, and research and development work

EQUIPMENT

DESCRIPTION

Din Abrasion tester - (Montech Rubber Testing Solutions)

Specifications:

- Contact Pressure: 2.5, 5.0, 7.5, 10.0, 12.5, 15.0, 17.5, 20.0 N

- Drum Diameter: 150 mm

- Drum Length: 460 mm

- Abrasion Sheet dimensions L/W: 472.5 mm (+2) x 400 mm

- Abrasion distance of sample: 40 m

- Compresion set

Compression set test is a reliable and repeatable method of testing the effect of compressive stress on an elastomeric material over a period of time. The test is mainly applicable to service conditions involving static stress and are frequently conducted at elevated temperatures.

Compression set test is a reliable and repeatable method of testing the effect of compressive stress on an elastomeric material over a period of time. The test is mainly applicable to service conditions involving static stress and are frequently conducted at elevated temperatures.The test results show the loss of elasticity of the material or its ability to return to its original thickness after prolonged compression, also known as material memory or permanent deformation.

EQUIPMENT

DESCRIPTION

Compression set apparatus

Specifications:

- Material: Stainless steel.

- Number of samples: 8

- Shore D: ISO R 868 / DIN 53505

- Resilience

Resilience is a function of both dynamic modulus and internal friction of a rubber. It is very sensitive to temperature changes and type of rebound resilience tester.

Resilience is a function of both dynamic modulus and internal friction of a rubber. It is very sensitive to temperature changes and type of rebound resilience tester.Rebound resilience tester is designed to measure percent resilience of a rubber compound as an indication of hysteretic energy loss that can also be defined by the relationship between storage modulus and loss modulus. The percent rebound measured is inversely proportional to the hysteretic loss.

EQUIPMENT

DESCRIPTION

Reboud Resilience Tester 5109 (Zwick/Roell)

Specifications:

- Pendulum mass: 0.252 Kg

- Pendulum energy: 0.5 J

- Pendulum length: 200 mm

- Angle of fall: 90 °

- Impact velocity: 1.98 m/s

Specimen dimension

- Diameter: 28 – 50 mm

- Thickness: 0 – 15 mm

- Fatigue

De Mattia fatigue tester gives an estimate of the ability of a rubber vulcanizate to resist crack growth of a pierced specimen when subjected to flexing. No exact correlation between these test results and service is implied due to the varied nature of service conditions.

De Mattia fatigue tester gives an estimate of the ability of a rubber vulcanizate to resist crack growth of a pierced specimen when subjected to flexing. No exact correlation between these test results and service is implied due to the varied nature of service conditions.Equipment

Description

De Mattia Fatigue tester (Alpha Technologies)

Specifications:

- Temperature: Ambient

- Frequency: 100 cpm

- Extension ratio: 1.6 – 2.4

- Capacity: 24 samples

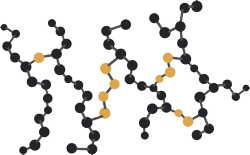

- Crosslink density

Crosslink density is a key property of rubber compounds and it refers to the concentration or density of chemical bonds, known as crosslinks, that connect polymer chains within the rubber matrix.

Crosslink density is a key property of rubber compounds and it refers to the concentration or density of chemical bonds, known as crosslinks, that connect polymer chains within the rubber matrix.The crosslink density mainly influence the final performance of rubber products such as its elasticity, strength, and resistance to deformation.

Techniques:

Equilibrium swelling

The most widely used technique in the rubber field. The volume of the rubber network increases when a crosslinked rubber is immersed in a suitable solvent. The determination of crosslink density is based on the Flory–Rehner model for swollen polymer network.

Equipment

Description

General chemical laboratory facilities (University of Twente)

Specifications:

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals

Temperature Scanning Stress Relaxation (TSSR)

Technique based on the evaluation of the stress relaxation of rubber when a constant strain and an increasing temperature are applied. (Non-isothermal relaxation behavior)

EQUIPMENT

DESCRIPTION

TSSR-Meter (Brabender)

Specifications:

- Measuring system: Heating / Cooling chamber with electric heating and air cooling

- Temperature range: 20 – 300 °C

- Heating rate: 0 – 4 K/min

- Strain: 0 –100 %

- Force load cell: 0 – 200 N

- Isothermal relaxation time: 0 – 1000 h

- Test body: Type 2 Dummbell specimen (International Standard ISO 37)

Thiol-Amine method

This technique Allows the differentiation between poly- di- and monosulfidic crosslinks by selective cleavage of bonds.

The soft probe, provides the cleavage of the polysulfidic bonds (mono- and disulfidic bonds remain). Meanwhile, the hard probe, provide the cleavage of the poly- and disulfidic bonds. (monosulfidic bonds remain). The total crosslink density is determined by swelling experiments.

EQUIPMENT

DESCRIPTION

General chemical laboratory facilities (University of Twente)

Specifications:

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals

Freezing point depression temperature

The crosslink density measurement by this technique is related to the magnitude of the freezing point depression temperature (ΔTf) of solvents imbibed in swollen vulcanizates. Comparison of the transition temperature values of a confined and free solvent allows qualitative determination of the degree of crosslinking of elastomeric compounds (depends on the mesh size of the polymeric network).

EQUIPMENT

DESCRIPTION

Netzsch 214 Polyma

Specifications:

- Cooling: Liquid nitrogen

- Protective gass: Nitrogen

- Purge gasses:Nitrogen / Oxygen / Air

- Temperature range: -170 – 600 °C

- Heating rates: 0.001 – 500 K/min

- DSC measuring range: +/- 750 mW

- Autosampler positions: 18

Mooney-Rivlin

This tecnique allows the determination of crosslink density by mechanical test (stress-strain measurements) based on the theory of rubber elasticity. This experiment provide the crosslink density and entanglements density of the vulcanized system.

EQUIPMENT

DESCRIPTION

Universal Testing Machine Zwick Z01 (Zwick/Roell)

Specifications:

- Force cell: 0.5 kN

- Grip type: Customizable

- Extensometer type: Clip

- Maximum travel: 1450 mm

- Maximum Speed: 1800 mm

- Temperature: Ambient

Universal Testing Machine Zwick Z10 (Zwick/Roell)

Specifications:

- Force cell: 0.1, 1, 10 kN

- Grip type: Customizable

- Extensometer type: Clip

- Maximum travel: 1450 mm

- Maximum Speed: 2000 mm

- Temperature: - 30 – 150 °C

- Bound rubber

Bound rubber is formed by interactions between the rubber chains and the filler particles. It is the macroscopic effect of the physical absorption, chemical sorption, and mechanical interaction between the rubber chains and filler particles. It is considered as a factor in the estimation of filler reinforcement.

Bound rubber is formed by interactions between the rubber chains and the filler particles. It is the macroscopic effect of the physical absorption, chemical sorption, and mechanical interaction between the rubber chains and filler particles. It is considered as a factor in the estimation of filler reinforcement.EQUIPMENT

DESCRIPTION

General chemical laboratory facilities (University of Twente)

Specifications:

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals

- Dispersion

Dispersion of fillers in the rubber compounds plays a fundamental role in the performance of rubber products. It it is define as the degree of uniform distribution of a filler's primary unit into a compound.

Dispersion of fillers in the rubber compounds plays a fundamental role in the performance of rubber products. It it is define as the degree of uniform distribution of a filler's primary unit into a compound.Understanding the dispersion of a mixed compound enables users to optimize process parameters and provide a quality control tool.

Equipment

Description

AlphaView Dispergrader (Alpha Technologies)

Specifications:

Aperture Size: 12 mm x 6 mm

Resolution:

- SR Version – 3.0 µm

- HR Version – 1.0 µm

Pixel Size:

- SR Version – 2.87 µm/pixel

- HR Version – 0.88 µm/pixel

- Melting point

Melting point is the temperature at which the material changes its phase from solid to liquid, under specified conditions. It is an important tool to identify the materials and to check the purity of the materials. This also helps in predicting the processing characteristics of materials.

Melting point is the temperature at which the material changes its phase from solid to liquid, under specified conditions. It is an important tool to identify the materials and to check the purity of the materials. This also helps in predicting the processing characteristics of materials.Equipment

Description

Melting Point Apparatus SMP3 (Stuart Scientific)

Specifications:

- Number of Samples: 3

- Temperature Range: ambient to 360 °C

- Temperature Resolution: 0.1°C

- Temperature Accuracy: ± 0.05 ºC at 20 ºC; ± 1.5 ºC at 360 ºC

- Ramp rates: 0.5 ºC – 10ºC per min in 0.1º C increments

Spectroscopic techniques

- Infrared Spectroscopy (IR)

Infrared spectroscopy (IR) is a non-destructive analytical method commonly used in the rubber industry for material characterization, research and development purposes and quality control of materials.

Infrared spectroscopy (IR) is a non-destructive analytical method commonly used in the rubber industry for material characterization, research and development purposes and quality control of materials.It is a powerful tool that provides valuable informationfor (fingerprint identification) about the chemical composition and molecular structure of polymeric materials.

Equipment

Description

Perkin Elmer Spectrum 100 series

Specifications:

- Sample: solid and liquid state.

- Scannin range: 370 – 7800 cm-1 (650 – 4500 cm-1 for ATR)

- Resolution: 0.5 cm-1

- Temperature: Ambient.

- Method: Transmission or ATR configuration.

- Ultraviolet Light Spectroscopy (UV/Vis)

Ultraviolet Light Spectroscopy (UV/Vis) serves as a fingerprint for identification and provides qualitative and quantitative analysis of additives that possess strong chromophores (e.g., antioxidants with aromatic rings). In this technique a given molecular species absorbs radiation only in specific regions of the spectrum where the radiation has the energy required to raise the molecules to some excited state. A display of absorption versus wavelength is called an absorption spectrum of that molecular species.

Ultraviolet Light Spectroscopy (UV/Vis) serves as a fingerprint for identification and provides qualitative and quantitative analysis of additives that possess strong chromophores (e.g., antioxidants with aromatic rings). In this technique a given molecular species absorbs radiation only in specific regions of the spectrum where the radiation has the energy required to raise the molecules to some excited state. A display of absorption versus wavelength is called an absorption spectrum of that molecular species.Equipment

Description

UV-Visible Spectrophotometer Cary 100 BIO (Varian)

Specifications:

- Scannin range: 200 – 850 nm

- Temperature range: 25 – 100 °C

- Temperature accuracy: 0.2 °C

Chromatographic techniques

- Gas Chromatograhy (GC)

Gas Chromatograhy (GC) is a technique used for the identification and quantification of a large range of low-molecular weight (MW) substances and additives.

Gas Chromatograhy (GC) is a technique used for the identification and quantification of a large range of low-molecular weight (MW) substances and additives. GC can be used as a relatively quick and simple technique to identify and quantify a number of analytes, including: residual monomers and oligomers, solvents, monomeric antioxidants, antiozonants, monomeric plasticisers, organic flame retardants.

Equipment

Description

Shimadzu GC-2010 Plus

Specifications:

- Carrier gass: He

- Purge gass: Nitrogen

- Detector: FID / TCD (simultaneously)

- Oven temperature range: 30 – 450 °C

- Column inner diameter: 0.32 mm

- Column length: 15 m

- Column film thickness: 0.25 µm

- High-Performance Liquid Chromatograhy (HPLC) and Liquid Chromatograhy-Mass Spectrometry (LC-MS)

HPLC and LC–MS instruments are usually employed to identify and quantify additives in rubber and plastic compounds that are either too involatile or insufficiently thermally stable to be analysed by either GC.

HPLC and LC–MS instruments are usually employed to identify and quantify additives in rubber and plastic compounds that are either too involatile or insufficiently thermally stable to be analysed by either GC.HPLC is very useful for the detection and quantification of relatively high-MW additives. It is the first-choice instrument for oligomeric or high MW antioxidants.

Equipment

Description

HPLC Value System Agilent 1100 Series (Agilent Technologies)

Specifications:

- Maximum flow rate: 10 mL / min

- Maximum pressure: 200 Bar

- Autosampling postions: 86

- Column temperature: 30 – 90 °C

- Detector: UV / VIS

- Thin-Layer Chromatograhy (TLC)

Thin-Layer Chromatography (TLC) is a relatively simple technique used for both the separation and identification of additives such as amine and phenolic antioxidants, and UV stabilisers.

Thin-Layer Chromatography (TLC) is a relatively simple technique used for both the separation and identification of additives such as amine and phenolic antioxidants, and UV stabilisers.EQUIPMENT

DESCRIPTION

General chemical laboratory facilities (University of Twente)

Specifications:

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals

Thermal techniques

- Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (DSC) measures the endothermic and exothermic transitions as a function of time and temperature.

Differential Scanning Calorimetry (DSC) measures the endothermic and exothermic transitions as a function of time and temperature.It is used to characterize polymers (thermosets, thermoplastcis and elastomers). In the rubber analysis it provides quality control fingerprint thermograms from which formulation deviations can be determined.

Analytical work can be performed in both a non-oxidising nitrogen atmosphere (most commonly used) and in an oxidising air atmosphere (for investigations involving oxidation stability).

DSC can be used to investigate the effectiveness of antidegradants and fire retardants in thermal stability studies of a rubber compound.

Transitions measured:

- Glass Transition (Tg)

- Melting point (Tm)

- Volatilisation of ingredients or absorbed substances (e.g. plasticisers, water or solvents)

- Crystallization

- Curing

- Cure kinetics

- Oxidation

- Heat capacity

Equipment

Description

Netzsch 214 Polyma

Specifications:

- Cooling: Liquid nitrogen

- Protective gass: Nitrogen

- Purge gasses:Nitrogen / Oxygen / Air

- Temperature range: -170 – 600 °C

- Heating rates: 0.001 – 500 K/min

- DSC measuring range: +/- 750 mW

- Autosampler positions: 18

- Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) is extremely useful technique for the analysis of rubber compounds related to their bulk composition and other important characteristics. It measures the mass of a sample as it is heated, cooled or held at a constant temperatura in a definded atmosphere and allows the detection of processes in which a mass variation occurs, such as: decomposition, sublimation, reduction, desorption, adsorption, etc...

Thermogravimetric Analysis (TGA) is extremely useful technique for the analysis of rubber compounds related to their bulk composition and other important characteristics. It measures the mass of a sample as it is heated, cooled or held at a constant temperatura in a definded atmosphere and allows the detection of processes in which a mass variation occurs, such as: decomposition, sublimation, reduction, desorption, adsorption, etc...TGA is especially useful to observe the thermal decomposition of materials and provides accurate quantification of the principal ingredients such as plasticisers, polymers, carbon black (CB) and inorganic species.

EQUIPMENT

DESCRIPTION

TGA Q550 (Thermal Instruments)

Specifications:

- Temperature range: Ambient – 1000 °C

- Temperature accuracy: 1 °C

- Heating Rate: 0.1 – 100 °C

- Furnace cooling (1000 to 50°C): < 12 min

- Sample weight capacity: 1000 mg

- Volume sample pan: 200 microliter

- Autosampler positions: 25

- Dynamic Mechanical Analysis (DMA)

Dynamic Mechanical Analysis (DMA) is an indispensable tool for determining the visco-elastic properties of polymeric materials. This technique consists of applying the sample to an oscillating stress (or strain) and recording the temperature-dependent visco-elastic properties of the material.

Dynamic Mechanical Analysis (DMA) is an indispensable tool for determining the visco-elastic properties of polymeric materials. This technique consists of applying the sample to an oscillating stress (or strain) and recording the temperature-dependent visco-elastic properties of the material.It is used to study the influence of molecular structure on the physical properties of polymers.

DMA measurements are also of utmost interest for the tire industry, since the prediction of tire performance is usually evaluated by considering the viscoelastic properties of rubber. The “magic triangle” principle of the tire industry is related to three main materialspecific requirements relevant to the tread, such as rolling resistance, wet grip, and abrasion resistance; targeting lower fuel saving efficiency, driving safety, and extended lifetime, respectively.

Possible studies to perform on polymeric materials:

- Influence of fillers

- Effect of plasticizers

- Influence of crystallinity

- Influence of molecular weight

- Compatibilization in blends

EQUIPMENT

description

Eplexor 2000 (Netszch)

Measurements:

DMA:

- Stress relaxation analysis

- Creep analysis

- Dynamic modulus

- Loss factor (tan δ)

- Conductivity

Specifications:

Temperature range: -150 – 500 °C

Frequency range: 0.01 - 100 Hz

Maximum static amplitude: 50 mm

Maximum dynamic amplitude: +/- 10 mm

Atmosphere: Air / Nitrogen

Coolant: Liquid nitrogen

Force cells: 50 / 500 N

Modes: Tensile / Double shear / Compresion / 3 point bending

Viscoanalyser VA2000 (Metravib 150)

Measurements:

DMA

- Stress relaxation analysis

- Creep analysis

- Dynamic modulus

- Loss factor (tan δ)

Specifications:

Temperature range: -150 – 400 °C

Frequency range: 0.001 - 200 Hz

Maximum static amplitude: 50 mm

Maximum dynamic amplitude: +/- 3 mm

Atmosphere: Air / Nitrogen

Coolant: Liquid nitrogen

Force cells: 150 N

Modes: Tensile / Double shear / Compresion

- Temperature Scanning Stress Relaxation (TSSR)

Temperature Scanning Stress Relaxation (TSSR) provides Information about relaxation behavior and structure of polymeric materials. It is particularly suitable for material development and quality control during production and allows fast determination of the crosslink density of rubber compounds.

Temperature Scanning Stress Relaxation (TSSR) provides Information about relaxation behavior and structure of polymeric materials. It is particularly suitable for material development and quality control during production and allows fast determination of the crosslink density of rubber compounds.EQUIPMENT

DESCRIPTION

TSSR-Meter (Brabender)

Specifications:

- Measuring system: Heating / Cooling chamber with electric heating and air cooling

- Temperature range: 20 – 300 °C

- Heating rate: 0 – 4 K/min

- Strain: 0 –100 %

- Force load cell: 0 – 200 N

- Isothermal relaxation time: 0 – 1000 h

- Test body: Type 2 Dumbbell specimen (International Standard ISO 37)

Specialized measurements and techniques

- Grinding

Grinding process is used to prepare samples and reduce the particle size of the materials.

Grinding process is used to prepare samples and reduce the particle size of the materials.EQUIPMENT

DESCRIPTION

Universal Cutting Mill Pulverette 19 (Fritsch)

Specifications:

- Suitable for: soft to medium-hard, fibrous and tough materials and plastics.

- Max feed size: 70 x 80 mm

- Speed: 300 – 3000 rpm

- Final fineness: depending on sieve.

- Sieve: 2 mm

- Devulcanization

Devulcanization process results in the selective breakup of the chemical network in the rubber compound. It consists of the cleavage of the intermolecular bonds of the network, such as carbon-sulfur (C–S) and/or sulfur-sulfur (S–S) bonds, which breaks down the macromolecular chains without damaging the backbone network and prevents material degradation.

Devulcanization process results in the selective breakup of the chemical network in the rubber compound. It consists of the cleavage of the intermolecular bonds of the network, such as carbon-sulfur (C–S) and/or sulfur-sulfur (S–S) bonds, which breaks down the macromolecular chains without damaging the backbone network and prevents material degradation.Devulcanization from rubber waste products has the greatest potential in terms of recycling, as vulcanized rubber waste can be mixed, processed, and revulcanized like virgin rubber.

EQUIPMENT

DESCRIPTION

Brabender Plastograph EC plus

Specifications:

- Effective mixing volume: 55/80 cm3

- Rotor type: Banbury / High shear

- Rotos speed: 0 – 150 rpm

- Temperature control: 25 – 300 °C

- Maximum torque: 200 Nm

General chemical laboratory facilities (University of Twente)

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals

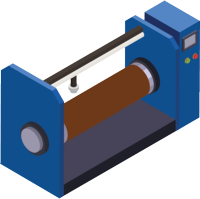

- Laboratory Abrasion & skid Tester (LAT) 100

Laboratory Abrasion & skid Tester (LAT) 100 is a equipment designed to accurately simulate a wide range of selectable road conditions for measuring abrasion and friction of tread compounds.

Laboratory Abrasion & skid Tester (LAT) 100 is a equipment designed to accurately simulate a wide range of selectable road conditions for measuring abrasion and friction of tread compounds.Tire producers can save time and money by evaluating tire properties before production starts.

Equipment

Description

Laboratory Abrasion & skid Tester (LAT) 100 (VMI)

Specifications:

- Disc material: High-grade electro corundum

- Disc grain size (Dry abrasion): 60

- Disc grain size (Wet handling): 180

- Test speed range: 0.02 – 100 km/h

- Measurement range: 0.001 – 20 km

- Slip angle: ±45 °

- Radial load regulation (Fz): 10 – 140 N

- Side force measurement (Fy): - 120 – 120 N

- Friction force measurement (Fx): 5 – 100 N

- Aging

Aging test allows to establish the changes in physical properties of a rubber compound for a given period at elevated service temperatures. This test attempt to predict the long-term life at lower temperatures.

Aging test allows to establish the changes in physical properties of a rubber compound for a given period at elevated service temperatures. This test attempt to predict the long-term life at lower temperatures.Equipment

DESCRIPTION

Convection Oven T6060 (Heraeus)

Specifications:

Max. temperature: 250 ºC.

Drying (Hot air) Oven LUT 6050 (Heraeus)

Specifications:

Max. temperature: 250 ºC.

Vacuun Oven OVL570 010J (Gallenkamp)

Specifications:

Max. temperature: 200 ºC.

Drying Oven (forced convection) FD 115 (Binder)

Specifications:

Max. temperature: 300 ºC.

- Soxhlet extraction

Soxhlet extraction is the procedure for removing the highly volatile organic additives present in the rubber products, such as rubber process oils, antioxidants, anti-ozonants, waxes, organic activators, accelerators, etc. This is important for the drinking water and food industry, where a maximum permissible extractable content is required.

Soxhlet extraction is the procedure for removing the highly volatile organic additives present in the rubber products, such as rubber process oils, antioxidants, anti-ozonants, waxes, organic activators, accelerators, etc. This is important for the drinking water and food industry, where a maximum permissible extractable content is required.Extraction process provides two different fractions:

- Extracts: solvent with high volatile organic materials (Detailed analysis of the organic materials can be performed subsequently).

- Extracted: rubber sample without the extractable organic material (Analyses of polymer, ash, fillers, etc., can be conducted).

EQUIPMENT

DESCRIPTION

General chemical laboratory facilities (University of Twente)

- Soxhlet-tyoe extraction apparatus

- Fumehood

- Balance Analytical

- Vacuum oven

- Suitable chemicals